- Micah

- 0 Comments

Evaluating Real-Time Particulate Monitors for Trustworthy Results

In industry where airborne particulate matter poses regulatory and operational challenges, the reliability of real-time monitoring systems is crucial to every aspect of site operation from workplace safety to environmental impact. Traditional methods like high-volume samplers provide useful historical data for regulatory and works licence purposes but lack the immediacy required for proactive dust emission management. This case study explores the effectiveness and reliability of Turnkey’s Osiris airborne particulate monitor and its proven ability to meet Australian regulatory requirements and support proactive dust management strategies.

To enhance the credibility of the Turnkey Osiris here in Australia a study was undertaken (2006 / 2007) by a NATA accredited environmental organization using standards AS3580.9.3 & AS3580.9.6 and European standard (In lieu of an applicable Australian standard method) EN 12341:1998 Determination of the PM10 fraction of suspended particulate matter – Reference method and field test procedure to demonstrate reference equivalence of measurement methods.

Objective: The primary objective of this case study is to evaluate whether Turnkey iPM and Osiris monitors provide trustworthy real-time results that can be acted upon to prevent further fugitive dust emissions and show equivalence to traditional high-volume samplers, thereby supporting effective dust emission management practices in Australian industrial and commercial settings.

Methodology for showing equivalence between high volume sampler and Osiris:

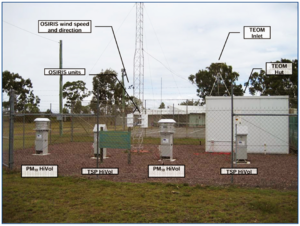

- Selection of Turnkey Instruments Osiris Monitors: The candidate instrument was required, under rigorous conditions, to demonstrate equivalency against the AS3580 high volume Sampler under real world weather conditions.

OSIRIS candidate units were employed for the study, Osiris monitors known for their one-second sampling rate and immediate alert capabilities. Using a photometer which gives simultaneous indications of PM1, PM2.5, PM10 and TSP with particle size measurements made through the diffracted angle of incidence of the laser in the counting chamber (diffraction angle α particle size). The accumulated count and calculated particle volume is then converted to a mass concentration per unit flow rate by applying an average particle density.

- Evaluation Criteria & Field Testing: accuracy & sensitivity to environmental conditions, is that the candidate instrument should show a strong correlation co-efficient to the high-volume sampler over repeated 24 hour averaged periods. Correlation co-efficient should meet the standard requirement of ≥0.95 with field tests that are conducted under real-world weather conditions to assess the performance of Osiris against AS3580 instrumentation.

Results: The field tests performed confirmed that Turnkey’s Osiris monitors consistently met or exceeded the standards set by EN12341 and AS3580 for particulate monitoring.

The OSIRIS instruments easily met the requirements of the standard for intra-instrument correlation with a correlation co-efficient of ≥0.99 for both size fractions against a standard requirement of ≥0.95.

It is worth noting that the level of correlation between the OSIRIS and high volume samplers was determined using the 10-minute average data, not the 24-hour averages as allowed by the standard. Taking this into consideration, the calculated correlation coefficients and standard errors between the candidate samplers provide an indication of the level of precision offered by the OSIRIS monitors.

Conclusion:

In addition to the proven reliable results of Turnkey’s Airborne Particulate monitors their real-time data collection and immediate alert capabilities enable proactive management of dust emissions, enhancing operational efficiency and regulatory compliance for Australian industries.

You can be sure that results obtained by Osiris are, at least, equal to results obtained by AS 3580 High Volume samplers as the iPM and Osiris use a unique application of Laser Forward Diffraction developed in house by Turnkey scientists – quite different from conventional Light Scatter techniques it’s because of this unique approach that Turnkey’s iPM and Osiris monitors have proven to be reliable tools for real-time particulate monitoring in Australian industrial and commercial applications. Their immediate reporting capabilities make them valuable assets for proactive dust management strategies. By integrating these monitors, companies can not only comply with regulatory requirements but also effectively control and mitigate airborne emissions in real time.

Recommendations: it is recommended that Australian industries consider adopting Turnkey iPM and Osiris monitors for their dust emission management strategies. Continued monitoring and periodic calibration are advised to maintain accuracy and reliability in real-time reporting, thereby maximizing the benefits of these advanced monitoring technologies. Ensuring a safer and more sustainable operational environment

References: For more detailed findings and the full report on the evaluation of Turnkey Osiris monitors against Australian standard High Volume samplers Reach out to a turnkey Representative here

Results: The field tests performed confirmed that Turnkey’s Osiris monitors consistently met or exceeded the standards set by EN12341 and AS3580 for particulate monitoring.

The OSIRIS instruments easily met the requirements of the standard for intra-instrument correlation with a correlation co-efficient of ≥0.99 for both size fractions against a standard requirement of ≥0.95.

It is worth noting that the level of correlation between the OSIRIS and high volume samplers was determined using the 10-minute average data, not the 24-hour averages as allowed by the standard. Taking this into consideration, the calculated correlation coefficients and standard errors between the candidate samplers provide an indication of the level of precision offered by the OSIRIS monitors.

Conclusion:

In addition to the proven reliable results of Turnkey’s Airborne Particulate monitors their real-time data collection and immediate alert capabilities enable proactive management of dust emissions, enhancing operational efficiency and regulatory compliance for Australian industries.

You can be sure that results obtained by Osiris are, at least, equal to results obtained by AS 3580 High Volume samplers as the iPM and Osiris use a unique application of Laser Forward Diffraction developed in house by Turnkey scientists – quite different from conventional Light Scatter techniques it’s because of this unique approach that Turnkey’s iPM and Osiris monitors have proven to be reliable tools for real-time particulate monitoring in Australian industrial and commercial applications. Their immediate reporting capabilities make them valuable assets for proactive dust management strategies. By integrating these monitors, companies can not only comply with regulatory requirements but also effectively control and mitigate airborne emissions in real time.

Recommendations: it is recommended that Australian industries consider adopting Turnkey iPM and Osiris monitors for their dust emission management strategies. Continued monitoring and periodic calibration are advised to maintain accuracy and reliability in real-time reporting, thereby maximizing the benefits of these advanced monitoring technologies. Ensuring a safer and more sustainable operational environment

References: For more detailed findings and the full report on the evaluation of Turnkey Osiris monitors against Australian standard High Volume samplers Reach out to a turnkey Representative here